Millennium Steel, June 2022

Latest news

News

Marker Robot Improves Product Performance

“A substantially higher production speed, as well as printing a marking of more characters on the flat and rounded sides of extremely hot rolls of steel, in less time”. Thus, the demands imposed by China’s leading steel producer when ordering the latest marker robot for their hot strip mill from Dutch manufacturing company, Tebulo Industrial […]

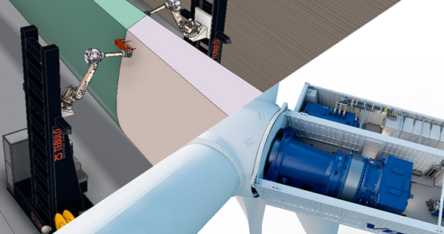

Best innovation award 2022 Tebulo / Vestas

27 January 2023 by Eize de Vries, Windpower Monthly This year, the best innovation award is shared by two very different ways to standardise wind turbine production for much larger volumes. Ground-breaking Vestas modularised nacelle concept Vestas’ containerised and modularised nacelle concept is a multi-purpose structure with container-specific add-on features for lifting, transportation and storage. […]

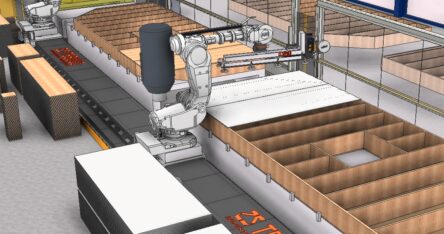

Robot Offers Solution to Housing Shortage

According to the forecasts, 1 million houses need to be built up to 2030 in order to meet the housing shortage in the Netherlands. In response, Vadeko commissioned system integrator Tebulo Industrial Robotics to develop a robot production line with 2 robots for the production of prefabricated house wall panels. With this solution, the company […]

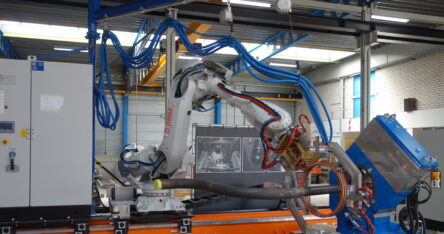

Robot With Sustainable Induction Technology Solution

In cooperation with Cojafex, Tebulo Industrial Robotics is developing a robot with induction technology and ‘external guided motion’ software for heat treatment of multiple bends in steel pipes (i.e. ‘pipe spool’) up to a diameter 20”. The tempering process reduces the stress caused within the bends of the pipe spools. The idea of deploying induction […]

Tebulo Industrial Robotics sold its North-America subsidiary

In 2008, Tebulo N.A. Ltd. was founded as a subsidiary to serve the North American market. Tebulo N.A. has operated under the mutual globally used trade name Tebulo Industrial Robotics since 2016. At the start of 2020, we decided to sell this subsidiary as this would allow both companies more freedom to develop and grow […]

Robotic Dross Removal Is The Future

Stahl und Eisen, Nr. 1-2 | Januar-Februar 2022 THAT’S WHAT IT’S ABOUT: The current production process entails pulling a preheated plate of steel through a 400- 500°C zinc bath. Operators must wear uncomfortable protective clothing, while manually scooping the dross from the bath in an extremely hot environment. It is a daily reoccurring and definitely […]