Robot With Sustainable Induction Technology Solution

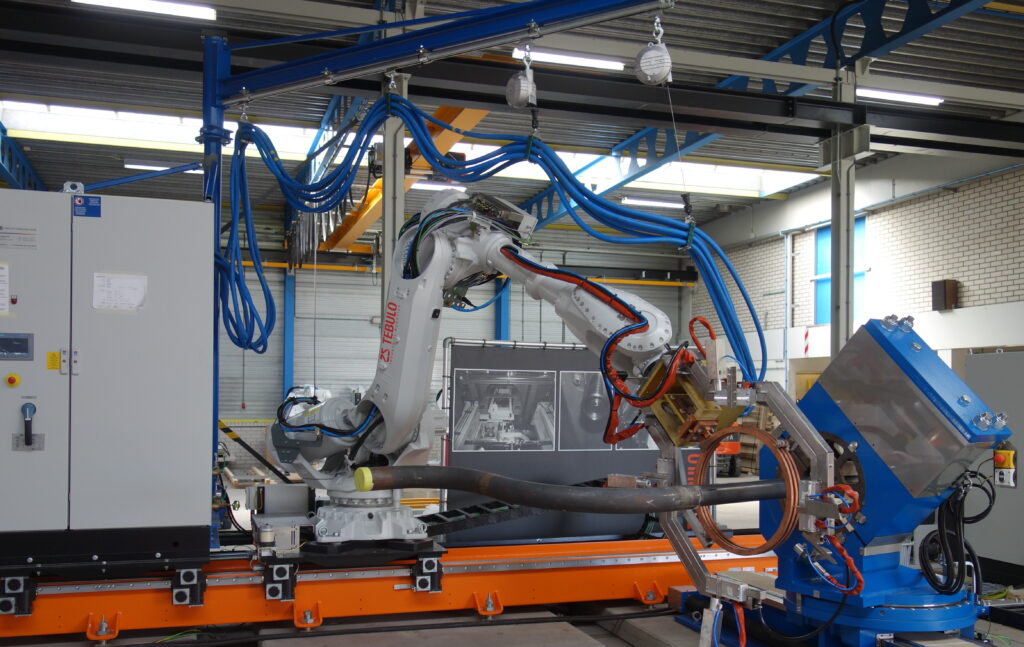

In cooperation with Cojafex, Tebulo Industrial Robotics is developing a robot with induction technology and ‘external guided motion’ software for heat treatment of multiple bends in steel pipes (i.e. ‘pipe spool’) up to a diameter 20”. The tempering process reduces the stress caused within the bends of the pipe spools.

The idea of deploying induction technology for this new robot system was launched by Cojafex, who utilized this for many years. Subsequently, Tebulo Industrial Robotics combined this technology with their many years of experience in the field of robotics and EGM software. Application of EGM software enables the system to easily follow any steel pipe with bends (i.e. ‘pipe spool’), without the need for complex robot programming. Based on the shape detected by the robot, the heat treatment will be done within the set parameters The system creates a measuring report that may be used for quality control purposes later on.

Before

Traditionally, heat treatment after a bending process on bends is done in an oven at approx. 600 °C, followed by cooling them. The new robot system is considerably better for the environment and leads to substantially lower energy costs. Moreover, by using this technology deformation of the end pieces (tangents) can be avoided.

Clamping System

The new robotic system is best compared to a so-called nerve spiral, a widely known game. Over a 9-meter long ‘‘track‘’, the robot moves up and down from one end of the steel pipe to the other. In this system, the 3- to 5-meter long pipe spool is always clamped at one end in a hydraulic clamping system. In the 0 position, the robot is positioned with the induction ring against the clamping system. From there, the robot scans the shape of the bend/spool. The system is provided with a clamping system on either side of the robot ‘‘track‘’. This enables the robot to work on one side, while the operator puts a new ‘‘spool‘’ at the free clamp.

Heating Process

Once the contours are scanned, the robot travels the same trajectory again while heat treating the bends in the spool. As soon as the robot detects a bend on its trajectory the induction ring the pipe automatically heated to around 600 °C. The (heare treatment) process speed is approximately 1 mm per sec. to allow a good heat distribution in the material. As soon as the robot reaches the pipe’s straight part again, induction heating is fully automatically switched off. Once the process is completed, the pipe spool is cooled down, prior to its removal from the clamp, while the robot returns to its 0 position.

Delivery

The new system was succesfully delivered to the Cojafex’s Norwegian sister company for testing, production and promotional purposes. Next, the sales activities for the new system will be launched. The present system is designed for pipe size 4” to 20”, but can also be made available for other sizes. In addition to that, the system can be executed with quenching instead of only tempering.