Robot Offers Solution to Housing Shortage

According to the forecasts, 1 million houses need to be built up to 2030 in order to meet the housing shortage in the Netherlands. In response, Vadeko commissioned system integrator Tebulo Industrial Robotics to develop a robot production line with 2 robots for the production of prefabricated house wall panels. With this solution, the company is able to save 31 minutes production time per element.

Vadeko, a renowned supplier of Prefabricated House Wall Panels for all large construction companies in the Netherlands, produces prefabricated inner and outer wall segments of up to 8-metre-long hinged roofs and floors. For this purpose, Tebulo Industrial Robotics develops a new production line with 2 collaborating robots which move along a 20-metre-long ‘track’. Currently, such so-called TFC (Timber Frame Construction) elements are still largely produced by hand.

Saving Time

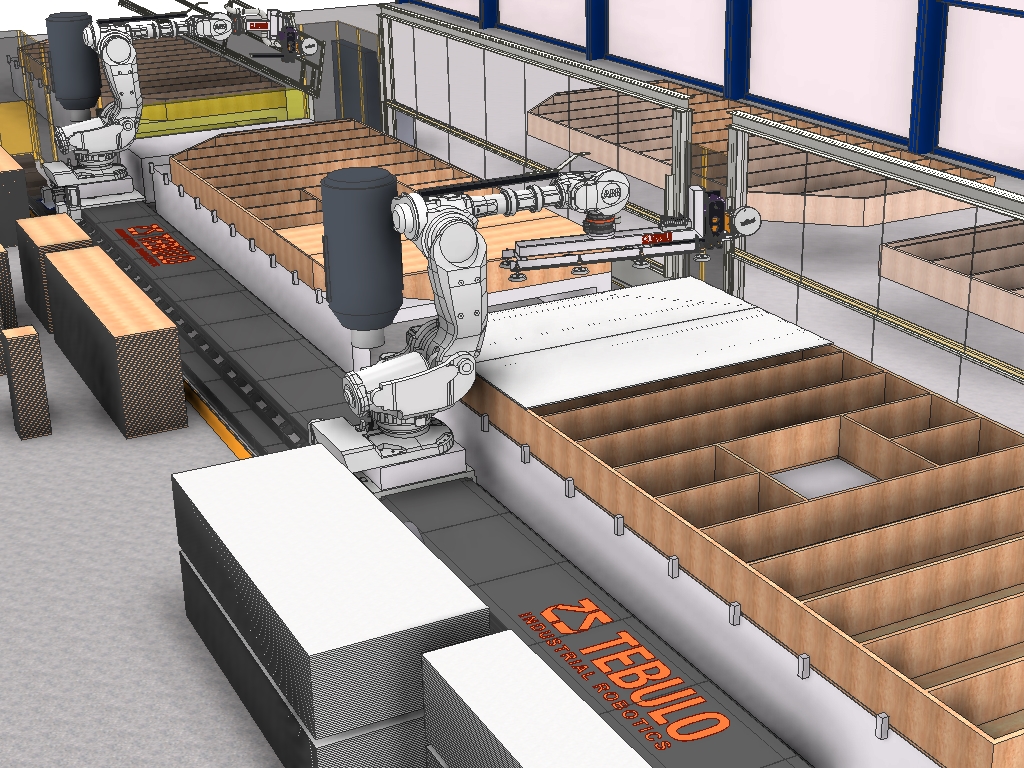

The production of a single complete wall element currently requires the combined efforts of 2 FTUs for 40 minutes. By integrating the robot line, the same wall element may now be produced in as little as 9 minutes, through a unique interplay between man and robot. How exactly does the new system work?

Unique Interplay

At the beginning of the production line, 10 to 36 cm thick timber frames for various HSB elements are manually joined by an operator. However, once the timber frame is ready, it is quickly pushed to the robot line and the first robot applies the cladding, nailing it to the frame on one of the two sides. The second robot ensures that the desired window and door openings are milled out in the right spot. The wooden frame is then rotated 180 degrees in one movement on the inversion table which is part of the production line, so that the cladding side is underneath. An operator then manually installs the cabling (fibre optic, electronic cables, etc.) and insulation, after which the same robots, a little further down the line, again carry out the required cladding and milling work, this time on the reverse side. The milled residual materials are removed from the production line by the unique interaction of both robots and then transferred to a ready-to-use waste container. It is interesting to note that both robots have a 325 kg payload.

Installation

On schedule, the 20-metre-long track was successfully completed and installed by Tebulo Industrial Robotics. The next step is to install the 1st robot followed in early 2023 by the 2nd robot. According to Tebulo, the greatest challenge for putting this robot line into operation is the meticulous configuration of the software. Contrary to a human being, a robot does not have any hand-eye-coordination. Moreover, programming the interaction between the two robots while making sure that they do not crash into each other, is extremely complex and requires much expertise.